Computational Capability

Multiscale Modelling of the Mechanics of Additively Manufactured Materials

• At atomic scale, the segregation of impurity elements may weaken the grain boundaries in AM materials, which can be studied by electronic structure calculations, such as density functional theory (DFT).

• At nano scale, the operation of persistent slip bands (PSB), which are responsible for materials ’ fatigue damage, can be influenced by the compositional/phase heterogeneities specific to AM materials (such as the dendritic structures). This effect can be investigated using molecular dynamics (MD) on isolated dislocations.

• At meso scale, with the dislocation mobilities characterized by MD simulation, the operation of PSBs and the collective motion of many dislocations can be simulated using dislocation dynamics (DD).

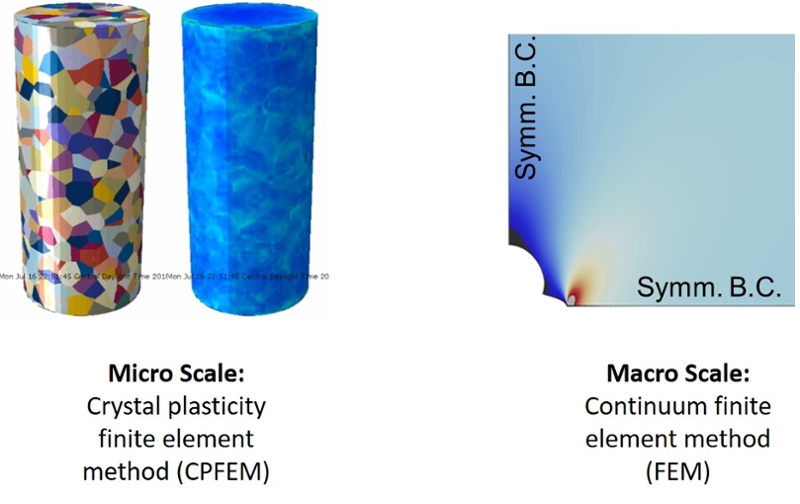

• At micro scale, the deformation of an aggregate of grains (such as the fine columnar grains unique to AM materials) can be modeled using crystal plasticity finite element method (CPFEM) simulations.

• At macro scale, the finite element method (FEM) simulations can capture the overall deformation of AM parts addressing the effects of surface roughness and complex geometry. It can also investigate the critical role of volumetric defects in AM materials (such as porosity and lack-of-fusion defects) in the initiation of fatigue cracks.